|

|

One of the things I like to point out about

building airplanes is, Don't let a percieved

lack of space hold you back.

Find a way.

This shot shows several things:

-

Our cabin sitting on a pair of Stanley,

adjustable saw horses.

We put common pipe insulation over them to

cushion the cabin.

-

Our wing is overhead on the wing-hoist we

made.

-

The main boom tube is visible in the lower

right.

|

|

|

|

Another shot of our work area.

The boom tube is sitting on another pair of

Stanley workhorses.

These are available at Home Depot, Lowes, et

cetera.

I highly recommend them.

|

|

|

|

Several pieces have to be added to the

ailerons before they can be mounted.

Clockwise from the top right.

-

Aileron hinge half one and hinge doubler

-

Aileron hinge half two and hinge doubler

-

Aileron control horn

-

Control horn doubler (more on this in the

next frame)

You'll notice that we've removed the pins

from the hinges. I feel this is the only

sane way to deal with mounting the

ailerons and flaps.

Before you knock out the hinge pins, be sure

to label both sides so that you can match

them back up later.

I just used a simple finishing nail, with the

point filed flat, to knock out the original

pins.

We made temporary pins out of common coat

hangers to use during assembly. These slide

in and out of the hinges much easier.

|

|

|

|

I normally don't add anything to the Odyssey

kit. I've seen too many homebuilt projects

come in extremely overweight.

But, in this case, I decided that a doubler

behind the aileron control horn would be a

good thing.

If you want to do something similar, I

recommend using a common index card as a

pattern. Cut it up with a pair of scissors

and fold it until it fits just right. Then,

just flatten it out and use it as a pattern.

|

|

|

|

This photo is a bit out of phase because it

shows a flap hinge being aligned, rather than

an aileron hinge. But, here's the technique

we use.

-

Start with one hinge half and locate it

with respect to the wing skin it belongs

to.

-

Tape down the ends of the hinge.

-

We use some common buck rivets to help

stabilize the hinge half. You can buy these

by the pound at Wicks or Aircraft Spruce.

-

Put two or three rivets in and check your

alignment.

-

Cover rivet area with tape.

-

Drill the remaining holes.

-

Cover all the rivet heads with tape

Once you have all the holes drilled, temp

riveted and taped, the hinge is actually

strong enough to test.

|

|

|

|

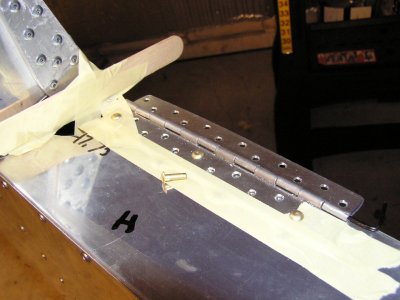

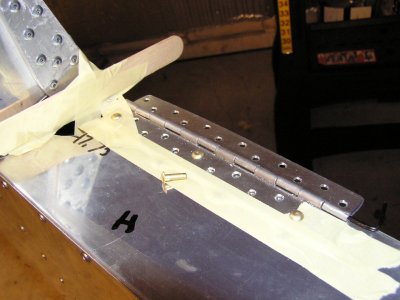

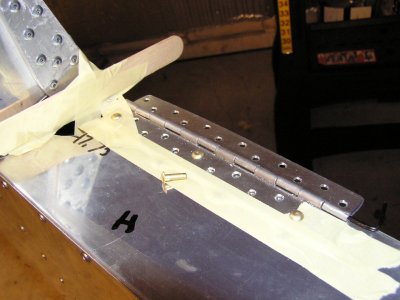

This shot shows the rivet area before the

remaining holes are drilled.

Once you have all the holes drilled, temp

riveted and taped, the hinge is actually

strong enough to test.

If you look carefully, you can see one of our

temporary, coat hanger, hinge pins.

The popsicle stick is a spacer that we tape

to an aileron bolt when the flaps are

mounted. It makes sure that 1/16th of an inch

space is maintained between the aileron horn

bolt and the flap.

|

|

|

|

This shot shows mounting the second half of

an aileron hinge.

We use the same, taping, and temporary

rivetting technique as show above. Once

you're done, you can actually test the

aileron movement before final glueing and

riveting

|

|

|

|

This shot shows how we use one of the

stainless steel yard sticks to represent a

continuation of the wing skin.

It also shows how we use a length of masking

tape to limit the travel of the aileron being

worked on.

|

|