|

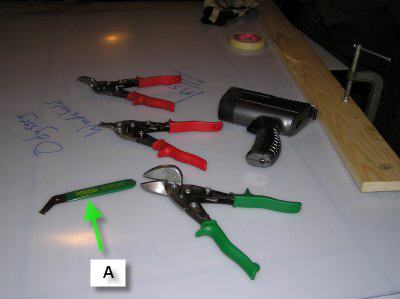

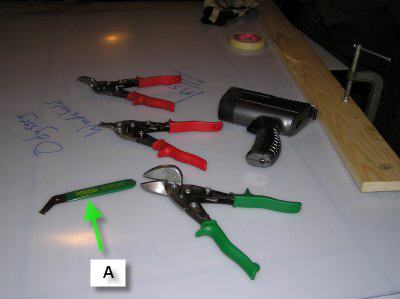

These are the tools we used for cutting the windshield

and windows:

- green handled linoleum cutter (A).

- green, red and orange handled tin snippers for left-hand,

right-hand and straight cuts. We used these on small

or curved sections.

- a rechargable light.

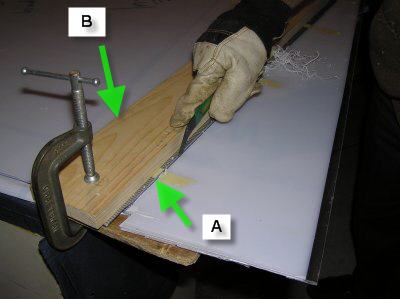

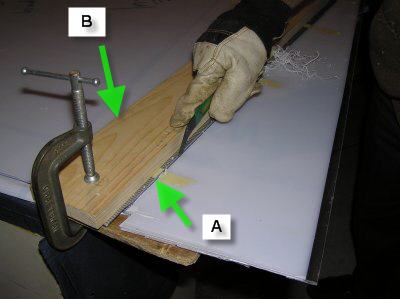

- a metal ruler, a board and two clamps. (You can see

the ruler in the next photo). We clamped the ruler and

board over the piece being cut so it would not shift. The

ruler is lined up on the cut line and is also a guide

for the cutting tool.

- masking tape. We used this to tape the ruler to the

cut line on the windshield. This kept the ruler from

shifting while we we clamped the board.

- gloves (seen in next photo) used just for protection.

|