|

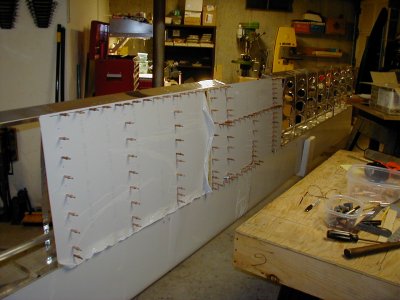

In week 4, we began the long process of skinning

the wings.

This operation is quite a long process in

building an Oyssey. But, it's ovbviously of

critical importance.

In any monococque construction, the skin

provides a great deal of the strength of the entire

structure.

The Odyssey skin is both riveted and bonded to

the ribs, D-cell and spars. Just like in painting a

car, proper surface preparation is the key to

success.

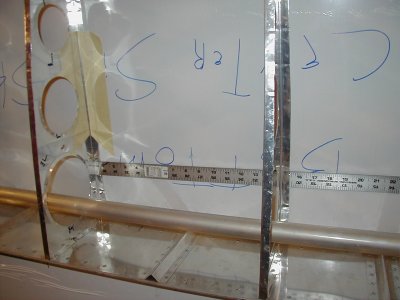

There won't be a lot of photos in this section.

Instead, we'll show you some of the tools we

devised and provide some tips and tricks along the

way.

|